Trend Analysis: Lead Acid to Lithium-ion Battery Conversion

Advantages of replacing lead acid batteries with lithium-ion batteries, and how to apply these in electric vehicles for material handling

Li-ion battery developments

Due to the significant development in Lithium Technology over the last 5 years, the demand for

replacing conventional Lead Acid (L/A) batteries with modern Lithium Ion based technology, is rapidly

increasing.

This application note will summarize the key benefits of replacing Lead Acid batteries with Lithium

based technology. In addition, the application note describes how the Lithium Battery should be

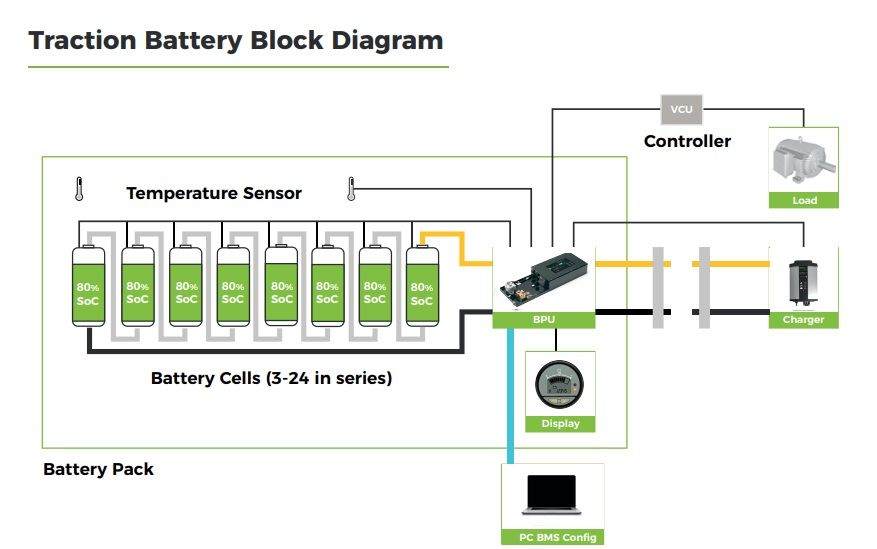

constructed, how the Battery Protection Unit (BPU) is integrated and how the battery performance can

be monitored and optimized.

Key benefits of lithium-ion compared to lead acid

-

1.

With Lithium batteries protected and monitored by an advanced Battery Management System(BMS), it is possible to avoid regular maintenance activities of the batteries, which are normally required with L/A.

-

2.

Lithium batteries can be charged in a normal indoor environment and have no requirements for special rooms that can withstand acid fumes associated with charging L/A batteries.

-

3.

Lithium batteries are a safe and environmentally clean product. They do not contain unhealthy acid

substances and environmental banned heavy metals such as lead.

-

4.

Reduce the energy consumption by 20-30% with Lithium battery, as the energy in charge and discharge will immediately be retained in the battery (LFP).

-

5.

Increase operational range and/or reducing battery size. The ratio is 5:9 comparing Ah capacity between Lithium (LFP) to L/A.

-

6.

Significantly increase cycle and calendar life as much 3 times with Lithium (LFP) compared with L/A.

-

7.

Improve the operation up-time by avoiding battery shift during operation.

-

8.

Optimize the performance of the battery by configuration of parameters in the BMS through an advance PC toolbox.

-

9.

Opportunity to operate in -20 to +45 C.

Further benefits of shifting from lead acid to lithium

Battery box

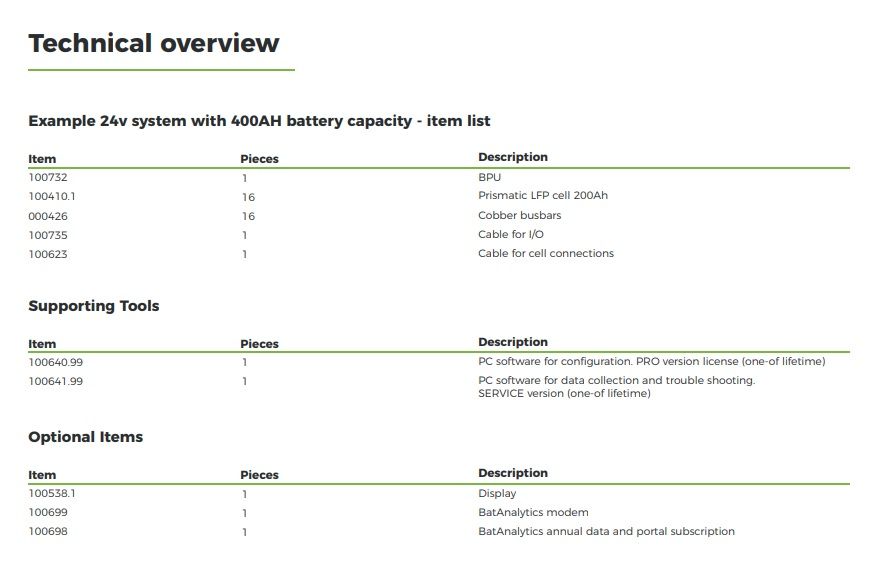

Basically the same battery box can be used as the one used with L/A.

For some applications like forklifts, the battery would require increased weight to achieve the counterweight. Steel plates can be used.

LiBAL BPU unit

The LiBAL BPU unit can be placed into all existing battery boxes, and is designed to stand upright to have easy access to PC communication port, cell monitoring wires, I/O cables and HV power line.

Prismatic cells

The prismatic cells can be placed inside an existing L/A battery box. Typically there will be a significant empty space due to the higher energy density of LFP compared to L/A. As a rule of thumb it should be expected that the same operational range can be achieved with half the nominal capacity.

The LFP cell can be supplied in 100, 180 and 200 AH capacity and can be mounted in 8s for 24 V, 15s for 48V and 24s for 80V. The cells can be mounted in parallel configuration up to 2000Ah.

48V example

In this 48V example, the complete battery pack is assembled. The BPU is installed and the cell monitoring wire to each of the 15 cells in series are mounted for cell voltage sensing and balancing.

In addition, 2 temperature sensors are positioned in the pack to observe the battery pack temperature. Each cell is connected with busbars and the power line goes through the BPU to measure current going in and out of the battery and to secure the battery with a charge/discharge relay. The BPU can be connected to a vehicle controller, motorcontroller and charger through CAN

Additional information

Configuration

The BPU can be connected to the BMS configuration tool through an RS232 connection. A USB to RS232 is supplied with the PC configuration tool.

Configuration of the BPU though PC toolbox PRO is facili-tated by Lithium Balance application Engineers, who will provide up to 5 hours of free support along with the soft-ware license. The software license is a one off purchase. Optional: Connect display/SOC indicator to BPU Optional: Connect to BatAnalytics datalogger and on-line battery data bank server.

Considerations

The following considerations should be taken, where Lithium Balance application engineers can support:

- Configuration of BMS in the BPU unit to ensure correct cell setting, I/O, charge/discharge compensation.SOC optimization and of course safety regulations incl. Charger setup.

- Battery configuration including mechanical drawing to ensure optimized size and battery cell configuration.

- Battery cost calculation incl. weight estimation, size, cell configuration.

- End-user TCO analysis consultancy to ensure correct parameters for calculation of cost/benefits between L/A and lithium.