i-BMS15TM

Description

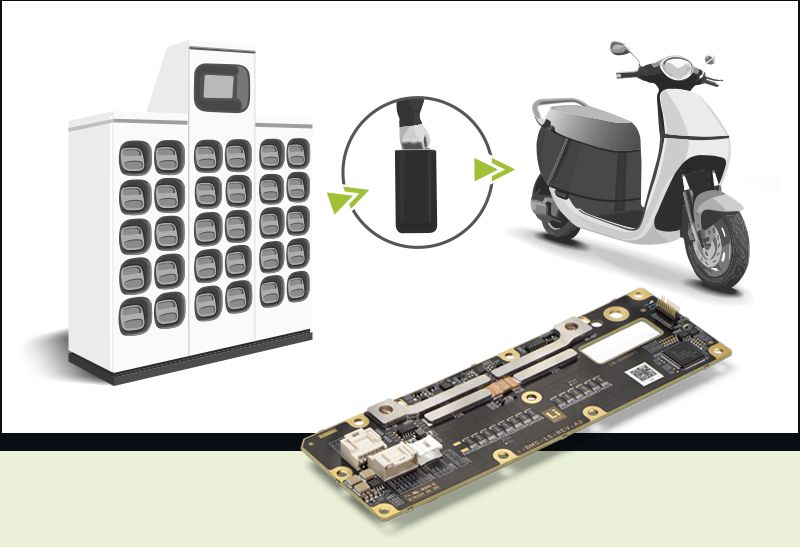

The i-BMS is an integrated BMS with 15 voltage channels managing applications up to 60V, developed for the cost-optimized mass-production of two and three wheelers, such as scooters and motorbikes, and other low voltage applications such as AGVs, and robots.

It is equipped with all hardware features to manage and maintain a battery without additional external components, including a built-in pre-charge circuit, on-board current measurement, mosfet power switches for battery disconnect, and a DC/DC power supply.

The i-BMS can support battery packs connected in parallel, features “Hot Swap” functionality, and includes advanced software algorithms for SOC, SOH, SOE, and SOP calculations.

Advanced BMS for Electric 2 & 3 Wheelers and Low Voltage Applications

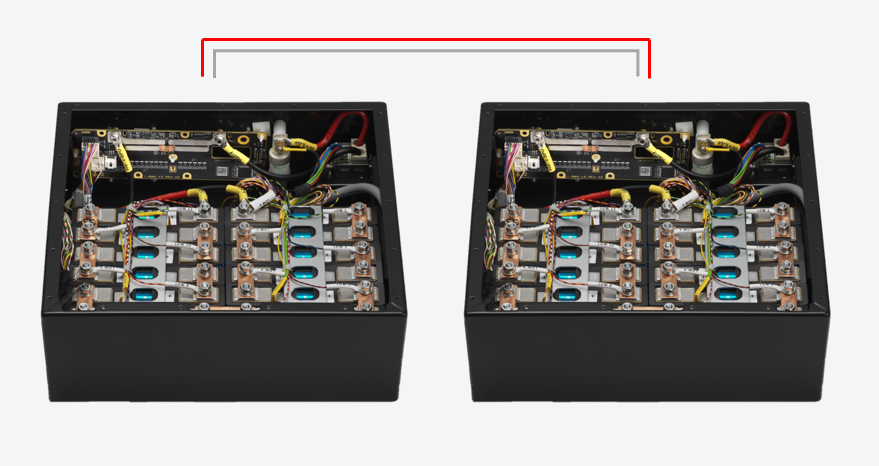

Parallel Pack Capable

The possibility to connect battery packs in parallel provides options for higher power density, more flexibility in battery design, and increased safety by limiting potential risks to a single battery pack instead of the full system.

Connect up to 6 of your battery packs in parallel with the i-BMS and swap these any time with easy via its “Hot Swap” feature.

Battery Hot Swap Support

Battery charging is time consuming and depending on use-case, may come with various issues, such as unwanted downtime in industrial applications or difficulty in charging on the road for EVs.

The i-BMS has the capability to completely eliminate these issues by supporting battery “Hot Swap” functionality.

Through its special algorithms, the i-BMS supports battery swapping for any use-case, whether it is to ensure continuous uptime for industrial applications or for eliminated charging time and range concerns for EVs via battery swap stations.

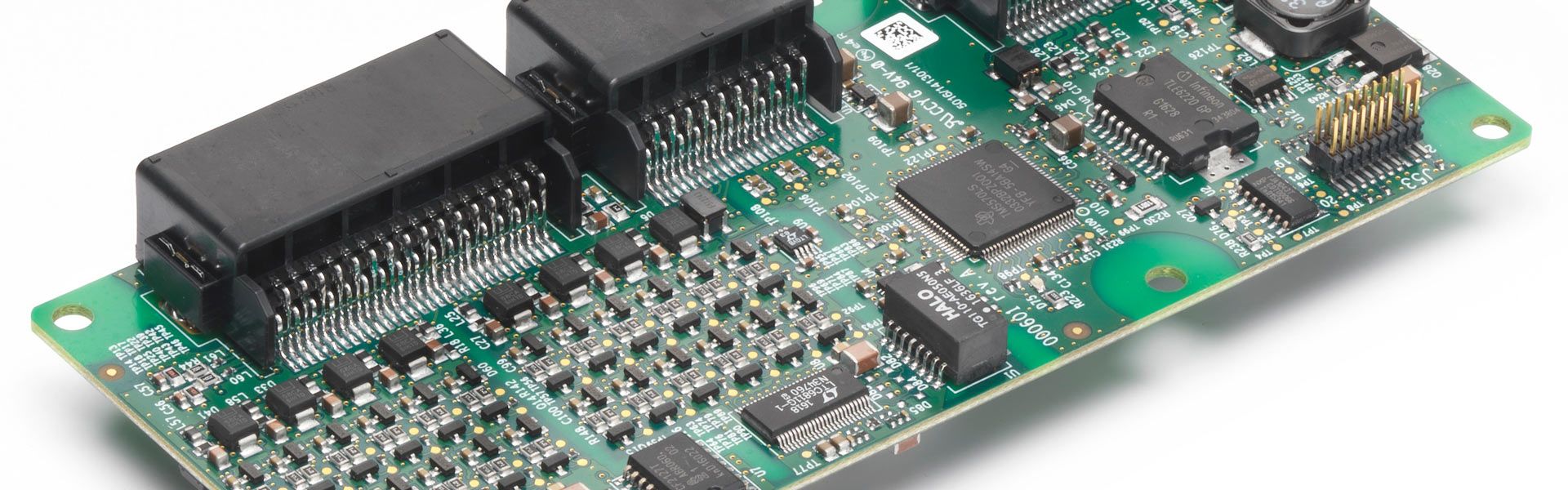

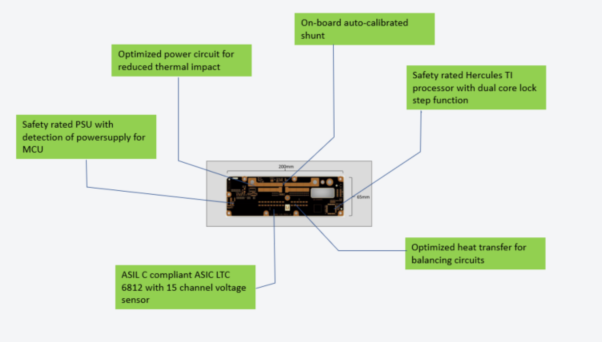

Integrated Battery Components & Efficient Design

While measuring only 200 x 65 mm, the i-BMS is equipped with all hardware features to manage and maintain a battery without additional external components:

- On-board auto-calibrated shunt

- Built-in pre-charge circuit

- MOSFET power switches for battery disconnect

- DC/DC power supply

- Optimized balancing and power circuits for advanced heat propagation

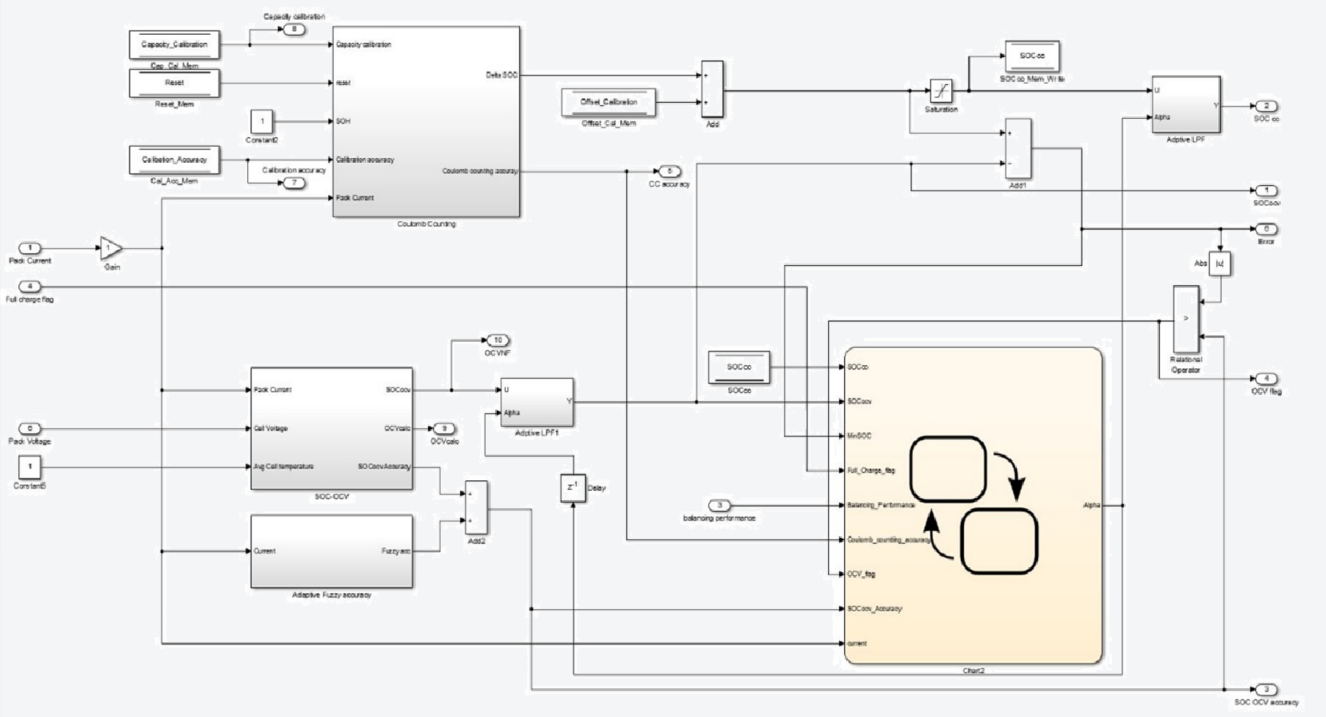

Advanced Algorithms

The i-BMS features state-of-the-art algorithms to ensure high precision SoX estimations. These include:

- Hybrid SOC estimation based on OCV, including rest

- SOC based on EOC calibration

- SOH based on OCV

- SOP with cell inner resistance

- Advanced SOE

Product ordering number:

-

i-BMS15: 100916

-

i-BMS CREATOR: 100910.99

Download

Specifications

| PARAMETERS | SPECIFICATIONS |

|---|---|

| SOC accuracy: | ±3% |

| SOH accuracy: | ±2% -point from 80% SOC |

| Balancing efficiency: | 200mA per cell |

| Accuracy of HV measurement: | ±100 mV |

| Accuracy of temperature measurement (NTC): | ±1 °C (from -10 to 70 °C) |

| Standby consumption (sleep mode): | 3.12 mW (Max) |

| Active consumption: | 1.5 W (Max) |

| Cell balancing current: | 200 mA |

| Cell voltage, current, and temperature sampling frequency: | 100 mS |

| Single cell voltage measurement accuracy (0.5 – 4.5 Vdc): | ±1,6 mV (at 25 °C) |

| Current measurement accuracy: | ±0.5% @ 120A |

| Range of temperature measurements: | From -40 to +120 °C |

| PARAMETERS | SPECIFICATIONS |

|---|---|

| Number of Voltage channels: | 8-15 channels |

| Range of HV measurement: | 17 – 60V |

| Detectable cell voltage range: | 0-5 Vdc |

| Maximum current, continuous: | 140A (under appropriate thermal conditions) |

| Peak current in maximum 10 seconds: | 200A (under appropriate thermal conditions) |

| Dimensions (L x W x H) & weight: | 200 x 65 x 18 mm, 93g |

| Temperature channels: | 4 on-board, 6 external (NTC) |

| On-board current measurement: | Yes – Auto-calibrated on-board shunt |

| On-board power disconnect: | Yes |

| CAN ports: | 1 |

| On-board RTC: | Yes |

| Pre-charge control on board: | Yes – 300 mS for 7 mF via 10 Ω |

| Bi-directional current protection: | Yes |

| Number of GPIOs: | 4 independent open drain outputs |

| Maximum drain voltage of GPIOs: | 36V (max 30V) |

| Maximum guaranteed GPIO continuous drain current: | 0.7A (max 0.5A) |

| PARAMETERS | SPECIFICATIONS |

|---|---|

| Communication CAN communication: | CAN 2.0 A/B; 11 bit and 29 bit ID’s |

| Charger Control Interface, Diagnostics Interface: | CAN, CAN UDS |

| Parallal pack / “Hot Swap” functionality: | Yes, 6 battery packs |

| Adjustable freeze frame memory: | Yes – Defaults to 18s of data with 150 entry samples leading to event |

| SOP estimation based on cell degradation: | Yes – 3 configurable time intervals |

| DC/DC auto-off shut-down: | Yes |

Related Products

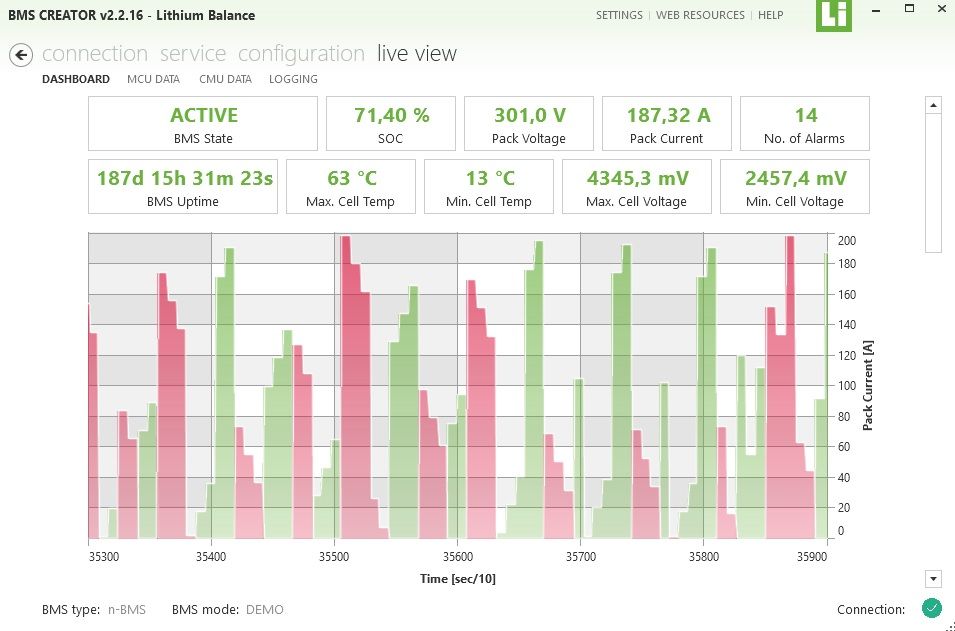

- Configuration software

- The i-BMS CREATOR software enables the battery designer to set up the BMS configuration for their specific application and selected battery chemistry.

- USB/CAN adapter

- For the i-BMS CREATOR software an adapter is required for USB to CAN conversion, which allows the connection from the BMS to the PC.

- Wire harness

- Tailor-made cell monitoring, temperature, I/O, and communication wire harnesses can be supplied for all i-BMS products.

- Shunts

- For all i-BMS products, a range of standard, compact, and high precision shunts are offered. The shunts can be selected to fit almost any application-specific currents.

- HAL effect sensor

- For all i-BMS products a range of standard high precision HAL effect sensors are offered. The HAL sensor can also be selected to fit almost any application specific currents.

- Fuses

- For battery systems, a further safety layer is configured using fuses. LiTHIUM BALANCE offers several fuses with ratings relevant for large format batteries.

- Relays

- For all i-BMS products a range of standard robust relays are offered. The relays can be selected to fit almost any application specific currents and voltage levels.

- Application support

- In order to ensure the smooth integration of the i-BMS into the system, we offer application support. In the software license 5 hours of free support is included. Application support beyond that is offered on an hourly basis.

- Training

- For a comprehensive introduction about the possibilities of our i-BMS, Li-ION technology, and battery integration, LiTHIUM BALANCE offers trainings tailored specifically to your needs.

- Remote surveillance

- For our i-BMS, a modem-based surveillance system can be connected to the BMS via CAN. The data is stored on a secure server and can be accessed from anywhere.

Fill out the form and we will contact you as soon as possible!

Or call +45 5851 5104