n3-BMSTM

Description

The n3-BMS is an ISO-26262 certified, flexible, cell chemistry agnostic distributed BMS with next-gen features implemented to address some of the most pressing safety, and performance challenges heavy vehicle OEMs face.

While the n3-BMS is ISO-26262 certified, it remains an off-the-shelf, flexible solution, offering significantly decreased time to market by cutting down years of work involved with the development and the certification process. This process involves submitting hundreds of documents to an accredited organization, rigorous testing, and in-depth safety considerations.

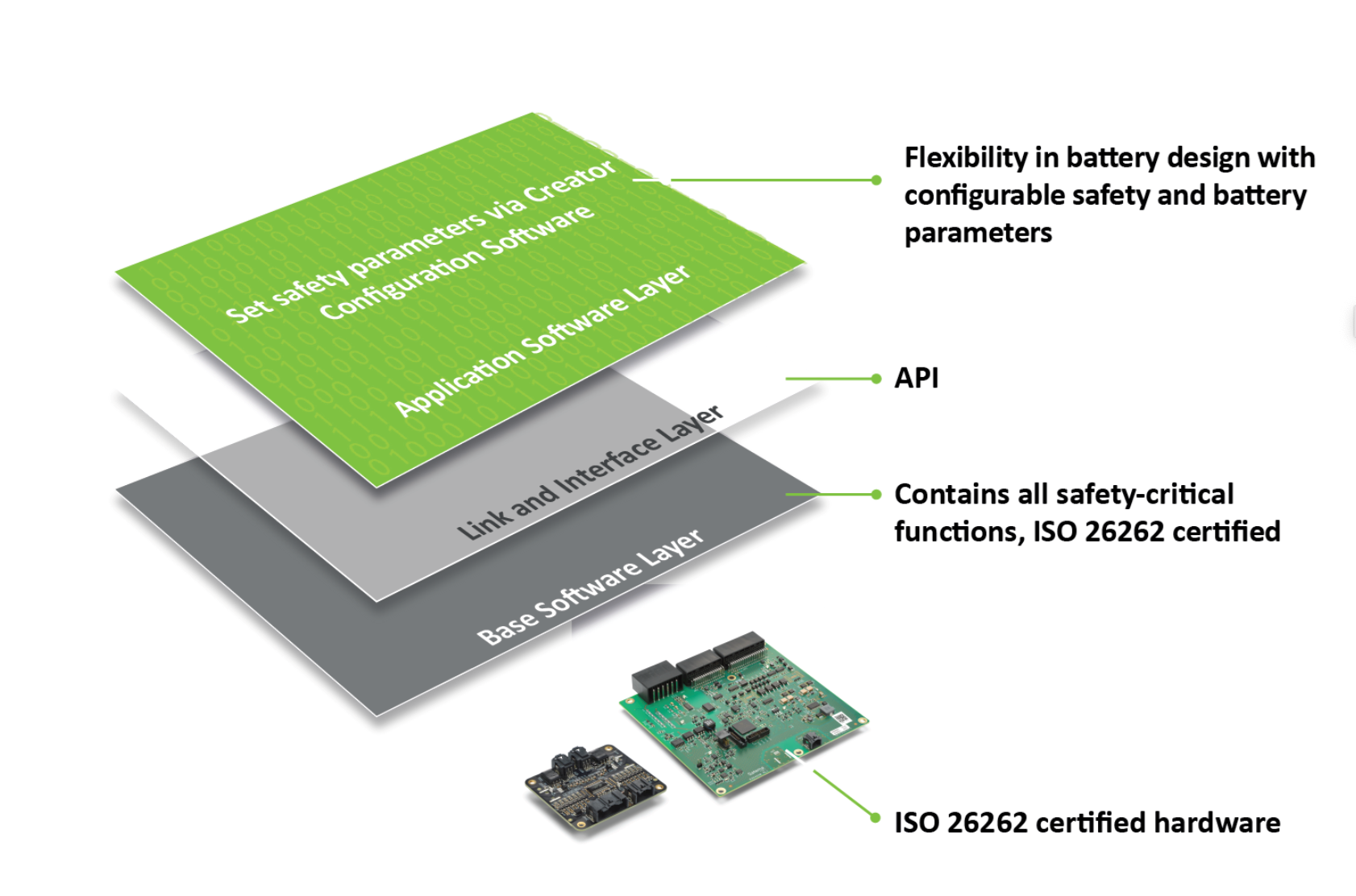

The n3-BMS features a unique software structure that separates functional safety-related features of the BMS into a Base Software Layer (BSW), with the remaining functionality placed under an Application Software Layer (ASW). This allows users to adjust key BMS parameters without risking the ISO-26262 certification. In addition, customers have the flexibility to use any number of CMU channels between 6 and 12.

Furthermore, with its dual-core lockstep CPU and ASIL C compliant ASIC, along with advanced algorithms, the n3-BMS is capable of high measurement accuracy.

Next-Gen Battery Management System for Trucks, Buses, and High Voltage Applications

Flexibility without re-certification

ISO 26262 Certified Off-the-Shelf

The development and functional safety certification of a BMS typically extends over several years. In contrast, the n3-BMS is already ISO 26262 ASIL C certified off-the-shelf, considerably reducing the time needed to bring the end application it is integrated in to market.

Adjust Battery Parameters Without Risk on Certification

The n3-BMS utilizes a unique software architecture that separates safety-related features into a so-called “Base Software Layer” (BSW) and places other BMS functionality in the “Application Software Layer” (ASW).

This design allows users to customize essential battery and safety parameters without any risk on the ISO 26262 certification or the need for any software updates.

High Power – Compact Size

The n3-BMS™ is tailored for high voltage and power applications, supporting up to 1000V and 2000A, making it especially suitable for trucks, buses, and other high voltage applications.

Despite this, its Cell Monitoring Unit (CMU), the board that is usually integrated into or around the individual battery packs & modules measures only 75 x 65 mm.

Product ordering number:

-

n3-BMS MCU: 100816

-

n3-BMS CMU: 100809

-

n3-BMS CREATOR: 100843.99

-

n3-BMS SERVICE: 100844.99

Download

Related Products

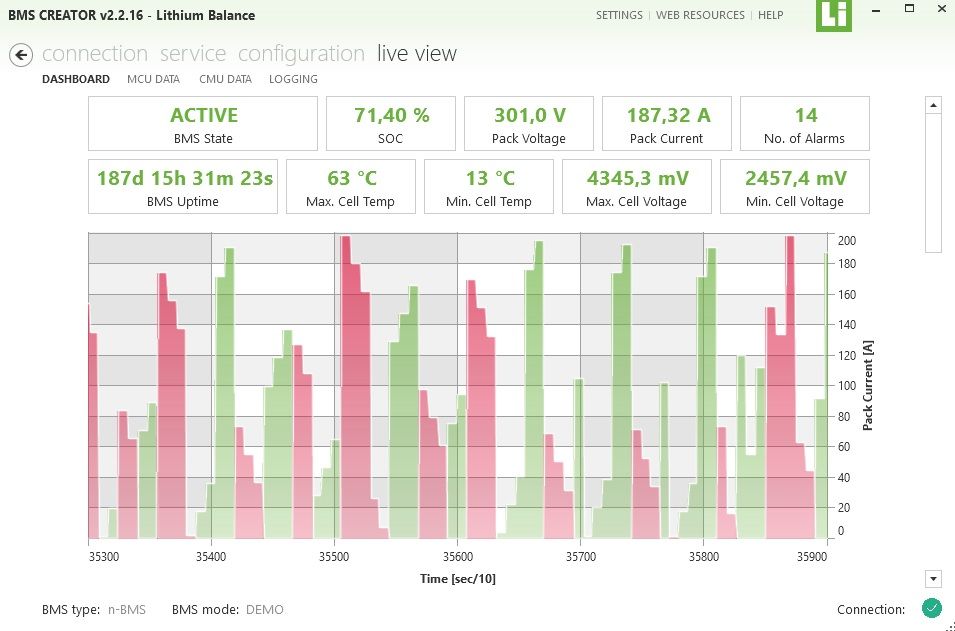

- Configuration software

- The n3-BMS CREATOR software enables the battery designer to set up the BMS configuration for their specific application and selected battery chemistry.

- USB/CAN adapter

- For the n3-BMS CREATOR software an adapter is required for USB to CAN conversion, which allows the connection from the BMS to the PC.

- Wire harness

- Tailor-made cell monitoring, temperature, I/O, and communication wire harnesses can be supplied for all n3-BMS products.

- Shunts

- For all n3-BMS products, a range of standard, compact, and high precision shunts are offered. The shunts can be selected to fit almost any application-specific currents.

- HAL effect sensor

- For all n3-BMS products a range of standard high precision HAL effect sensors are offered. The HAL sensor can also be selected to fit almost any application specific currents.

- Fuses

- For battery systems, a further safety layer is configured using fuses. LiTHIUM BALANCE offers several fuses with ratings relevant for large format batteries.

- Relays

- For all n3-BMS products a range of standard robust relays are offered. The relays can be selected to fit almost any application specific currents and voltage levels.

- Application support

- In order to ensure the smooth integration of the n3-BMS into the system, we offer application support. In the software license 5 hours of free support is included. Application support beyond that is offered on an hourly basis.

- Training

- For a comprehensive introduction about the possibilities of our n3-BMS, Li-ION technology, and battery integration, LiTHIUM BALANCE offers trainings tailored specifically to your needs.

Fill out the form and we will contact you as soon as possible!

Or call +45 5851 5104