A Passion for Quality

All Green Vehicles is the leading supplier of electric vehicles in the Netherlands. We take a look at some of their more interesting offerings.

A Leading Supplier

All Green Vehicles (AGV) is the leading supplier of high speed electric vehicles in the Netherlands. AGV both converts and sells electric vehicles from a range of OEMs including Ford, MAN and Oullim of Korea to name but a few. AGV has also been involved in the conversion of Toyota Priuses to plug-in hybrids and the development of an electric version of the Spirra sports car from Korea. Follow this link to see the Electric Spirra in action. AGV headquarters is located in a state of the art production facility in Oosterhout, Netherlands and has a current production capacity of over 600 vehicles/annum.

To make a reliable, safe and refined electric vehicle is not a trivial challenge. Everything from the Battery pack to the chassis and drivetrain electronics need to be carefully engineered.

AGV

All Green Vehicles of the Netherlands was established in 2007 to supply electric vehicles to the Benelux region. AGV have distinguished themselves among their competitors by their attention to detail and their focus on quality AGV work with primarily commercial vehicles as these can best benefit from the trade-off between range and running costs for electric vehicles. Two of the vehicles that stand out in the AGV range are the AGV Connect Light Goods Vehicle (LGV) and the AGV MAN Heavy Goods Vehicle (HGV).

The AGV Connect

The AGV Connect is based on the Ford Transit Connect. With a top speed of 130km/h and a range of 130km, the AGV Connect is perfect for urban deliveries. The launch customer for this range of vehicles was the Dutch power utility Eneco.

Battery management at its heart

The battery management system is tightly integrated with the motor controller ensuring efficient and safe operation of the batteries right across their SoC range.

The Drivetrain

Starting with the drivetrain, DC brushless motors were chosen as this type of electric motor is more efficient, more compact and has lower cooling requirements than your typical AC induction motors, which are of course, cheaper. The motor has been mounted to maintain the crumple zones essential for crash safety.

The motor controller is coupled with the LiTHIUM BALANCE Battery Management System to ensure the drivetrain utilises the batteries safely and efficiently. The BMS broadcasts continuously over CAN to provide the drivetrain with battery status information, such as SoC, allowable discharge and regen (regenerative braking) currents. Errors and warnings are also broadcast over CAN allowing the drivetrain to make intelligent safety decisions.

The transmission is a single speed, reduction gearbox. The usual trick of vehicle converters, using the standard gearbox and fixing it in second gear, removes some of the benefits of the electric drivetrain including efficiency, with more meshing gear sets creating losses and torque transfer, electric motors generate high levels of torque at low speed, far in excess of what an internal combustion engine of a similar power would deliver. This means that the electric motor needs to be down rated to prevent it from stripping the cogs in a normal gearbox.

The Cabin

The dashboard instruments have been professionally customised so that the warning lights are for an electric drivetrain rather than the original ICE, the gear shifter is also a dedicated unit for the electric drivetrain, giving an overall impression of being in an OEM manufactured vehicle.

On the road, the common mistakes of mounting the brake vacuum pump too close to the engine bay bulkhead, so that you can hear it hammering away intrusively every time you hit the brakes are absent, as is steering pump whine. A lot of work was done to reverse engineer the vehicle onboard electronics so that all the electronic features of the original vehicle are still present such as ABS brakes, airbags, the in car entertainment system and the heating system. The heating system is of course supplemented with an additional electric heating element.

The Battery

The battery pack is the heart of an electric vehicle. AGV have mounted the 25.7kWh pack under the floor above the rear axle. This low position provides good ride and handling as it lowers the vehicle’s centre of gravity and puts weight over the rear axle to improve the ride.

The battery box is fabricated aluminium to provide strength while minimising weight and it incorporates the contactor box. The contactors are controlled by the LiTHIUM BALANCE Battery Management System, whereby in the event of a critical error, the system will open the contactors rendering the battery safe.

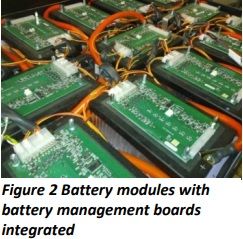

The cells are lithium ion polymer pouch cells built into a dedicated 4p8s module integrated with the battery

management system from LiTHIUM BALANCE.

The dimensioning of the pack and the mounting of the modules within the pack have all been done so as to optimise the range and maximise the safety, with modules being fixed top and bottom within the pack. A steel skid is placed ahead of the battery box to protect it from debris on the road.

The end result of all this effort has been an OEM quality electric vehicle that excels due to its refinement and driving characteristics while looking as if it has been engineered to last.

The AGV Man

This represents the perfect marriage of application to solution. Trucks are typically noisy, smelly brutish things with complicated gearboxes and noisy brakes. When used in an urban environment to deliver goods from depots to sales outlets, we all know how poorly they fit in.

The AGV MAN benefits from the torque rich nature of an electric drivetrain, once again using a brushless DC motor, to provide near silent travel and a relaxing driving experience as the vehicle moves away from standstill up to 100km/h without a single gear change and very little noise beyond the gentle wind rustle around the cabin.

With a modular 120kWh battery pack onboard located in 5 boxes, both sides and in between the chassis rails, and a short motor bolting directly to the axle differential, the packaging is exceptionally neat allowing coachbuilders to mount vehicle bodies without any compromise on space or positioning.

The battery is controlled by the LiTHIUM BALANCE s-BMS system which communicates with the motor controller providing safe charging and operation including a gradual reduction of power as the battery SoC drops to extend range and protect the batteries. On such heavy vehicles, the application of regenerative braking provides real benefits lessening braking loads while saving energy.

Once again, masterful work has been done to reverse engineer the chassis electronics to provide a fully functioning cabin and dashboard and the overall fit and finish is of the highest order.

Passion

AGV have a number of other electric vehicles on offer ranging from a smart Ford Transit van conversion with a very low battery pack that sits under most of the van floor through to an 18 tonne HGV.

What marks AGV out as a producer of electric vehicles is passion, a passion for good engineering, a passion for making the product right and a passion for quality, it’s a passion you can feel when you drive their vehicles.

Let’s Celebrate!

LiTHIUM BALANCE received the prestigious Frost & Sullivan 2009 European Automotive Powertrain New Product Innovation Award and are runners up in the 2010 Eurecan Venture Contest.

No small task

Managing a 120kWh battery pack with a long communication cable that runs up to two metres between battery boxes and the need to balance 360Ah of battery requires a lot from the battery management system.

Frost & Sullivan presented LiTHIUM BALANCE Battery Management Systems A/S with the ‘2009 European Automotive Powertrain New Product Innovation Award’. Points that counted in LiTHIUM BALANCE’s favour, according to Frost & Sullivan Research Analyst Bharath Kumar Srinivasan were the vehicle-to-grid features and the significant life extension of battery cells due to the s-BMS’s performance. The extended battery life translates to sustained vehicle performance over time.

LiTHIUM BALANCE was also a runner up in the Eurecan European Venture Contest which saw 987 applicants from all over Europe compete for the top honors. LiTHIUM BALANCE represented by Lars Barkler made it through, first to the last 150, before going on to the last 25 and finally ending up second in the Cleantech category. More cause for celebration!